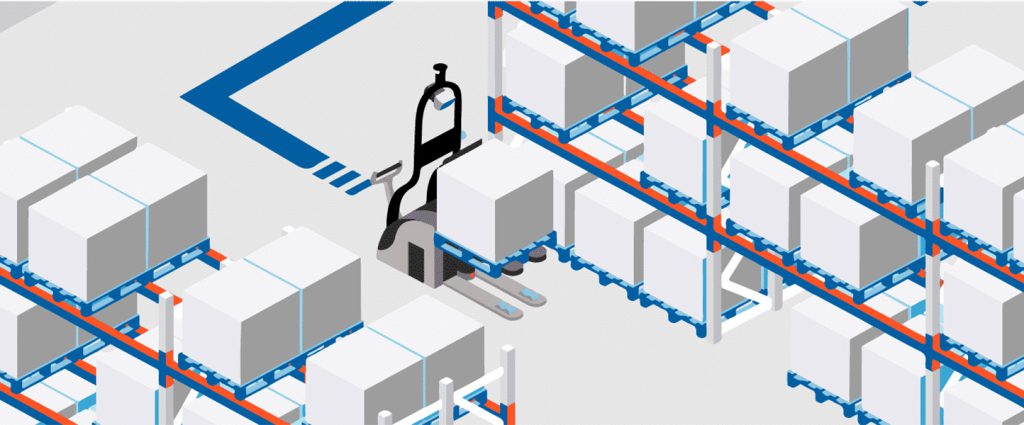

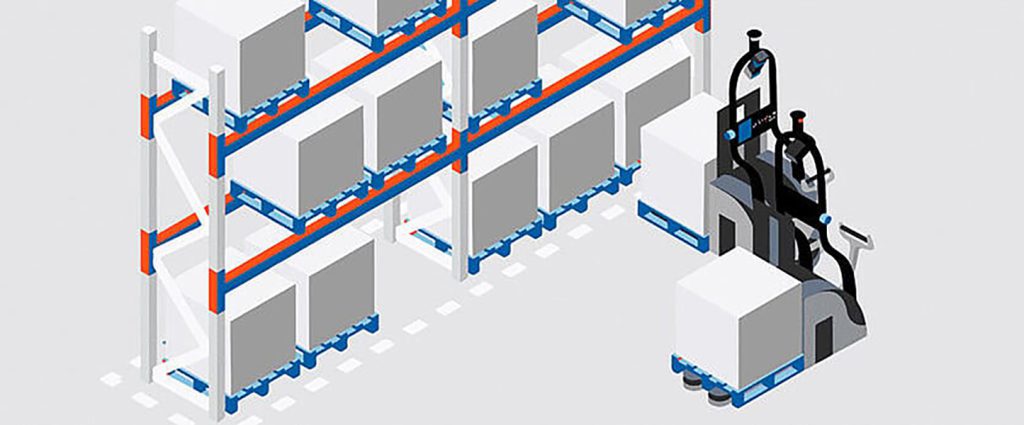

In warehouses or distribution centers, pallets are moved from inbound docking to storage area several times per day. Usually, an operator transports one or several pallets from receiving to end of aisles where vertical lift trucks can store them in high racking.

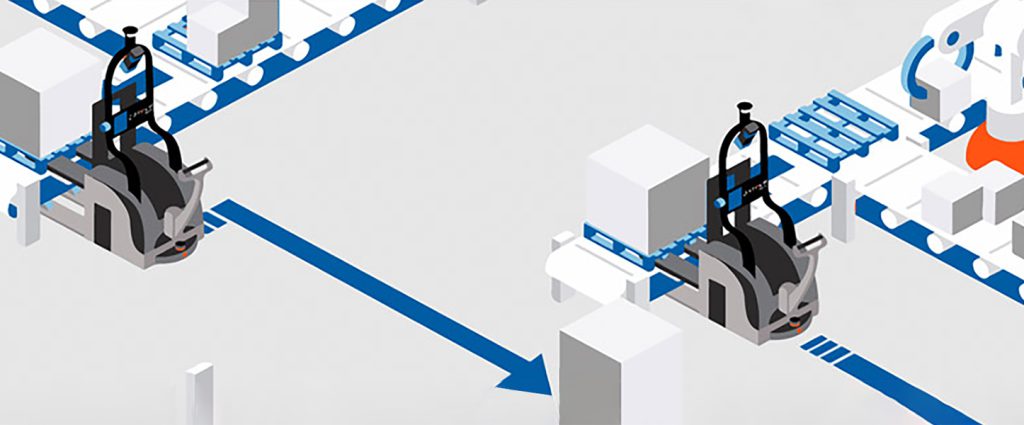

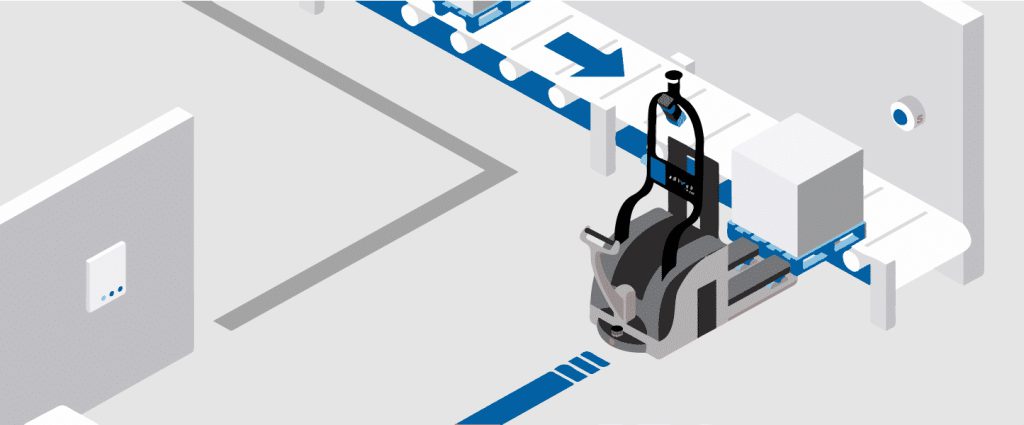

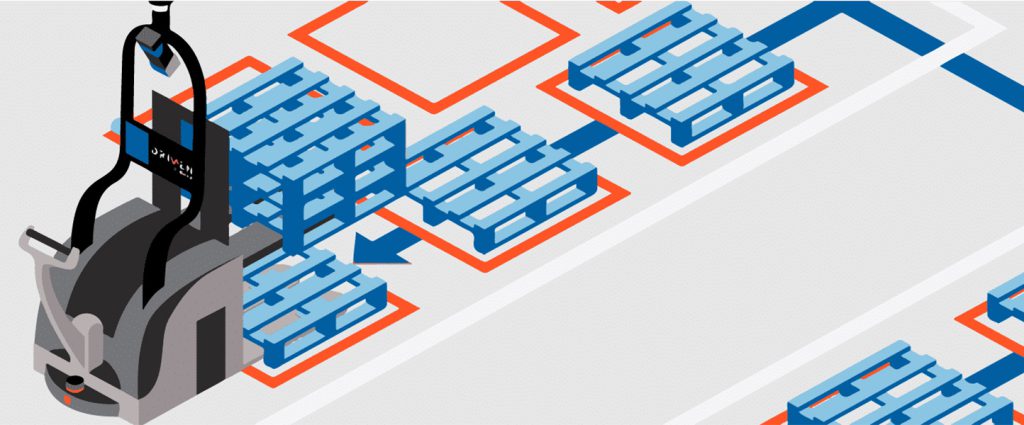

Robots Driven by BALYO can be used to replicate the path of manual drivers and complete long distance transports of pallets to end of aisles. Dedicated buffer areas can also be created throughout the warehouse where Driven by BALYO lift trucks will drop pallets that have to be stacked.

The BALYO robot range allows our customers to automate the full process: pallet transfer using robotic pallet trucks and racking storage using autonomous reach trucks or VNA.

SOLUTIONS

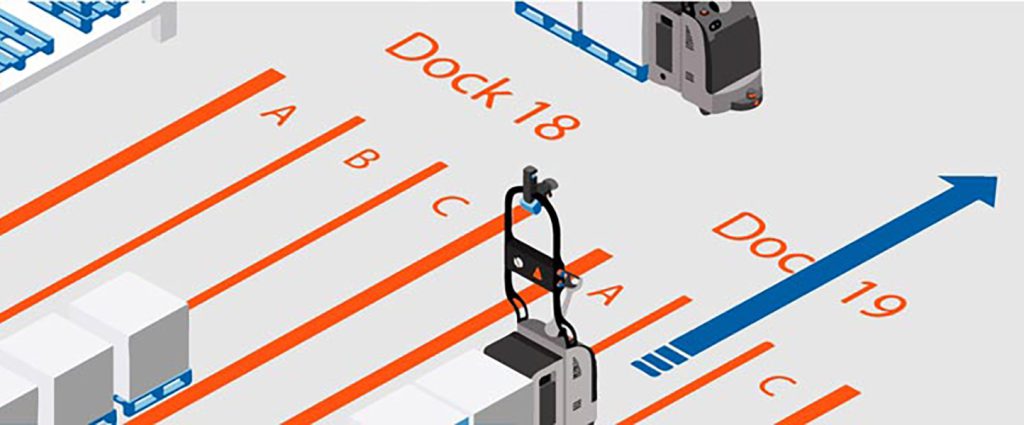

Intelligent Pallet Detection: This feature allows a robot to scan staging lanes using its safety laser, in order to detect and remove pallets from the zone. After a scan, if a pallet is detected, the information is sent by the robot to the BALYO Robot Manager that will trigger a pick mission. This robotic solution is fully autonomous and removes the need for a manual operator to trigger pallets removal.